Belt Conveyors

Belt Conveyors: The Backbone of Modern Material Handling System

Belt conveyors have become a cornerstone of industrial and logistical operations, enabling efficient material handling in manufacturing and various industries. This article aims to demystify belt conveyors’ workings, applications, and advantages, leveraging Natural Language Processing (NLP) to present the information intuitively and in a reader-friendly manner.

What Are Belt Conveyors?

A belt conveyor is a continuous loop made from rubber, fabric, or metal materials. Electric motors drive the system, which moves goods or materials along a fixed route. These systems offer high versatility and can be customised to meet the specific needs of various industries, load capacities, and operational environments.

- Conveyor Belt: The carrying medium that transports materials.

- Pulleys: Drive and tail pulleys guide and drive the belt.

- Rollers: Support the belt along its length, reducing friction and wear.

- Motor and Drive System: Provides the power to move the belt and load.

- Frame and Supports: Offer structural integrity to the entire system.

Applications of Belt Conveyors

Belt conveyors are indispensable across diverse industries, each benefiting from their efficiency, adaptability, and scalability. Some prominent applications include:

- Manufacturing and Assembly Lines: Moving parts between workstations and enhancing efficiency in just-in-time production systems.

- Food Processing: Ensuring hygienic transport of food products with stainless steel and washable belts for easy cleaning.

- Logistics and Warehousing: Facilitating the movement of packages in distribution centres; integral to sorting and packing processes.

- Agriculture: Transporting grains, seeds, and harvested produce, used in silos and processing plants.

Advantages of Belt Conveyors

Belt conveyors offer numerous advantages, making them a preferred choice in material handling:

- Efficiency and Speed: Capable of transporting materials over long distances with minimal effort. Speeds can be adjusted to suit specific operational needs.

- Versatility: Can handle various materials, from lightweight packages to heavy bulk loads, adaptable to different terrains including inclines and declines.

- Cost-Effectiveness: Lower energy consumption compared to alternative transport methods, reducing manual labour requirements and leading to long-term savings.

- Safety: Minimises the risk of workplace injuries by automating material transport, with features like guards and emergency stop mechanisms.

- Environmental Benefits: Modern systems incorporate energy-efficient motors and recyclable materials, lowering dependence on fuel-powered transportation.

Technological Advancements in Belt Conveyors

Recent innovations have elevated the capabilities of belt conveyors, ensuring they meet the demands of modern industries:

- Smart Conveyors: Equipped with IoT sensors for real-time monitoring of performance and maintenance needs. Predictive analytics helps prevent unexpected downtimes.

- Advanced Materials: Development of lightweight, durable, and heat-resistant belt materials with anti-static and fire-resistant properties for specific applications.

- Automation and Integration: Seamless integration with robotics and automated systems, with improved control systems for better synchronisation with production lines.

Challenges and Solutions

Recent innovations have elevated the capabilities of belt conveyors, ensuring they meet the demands of modern industries:

- Smart Conveyors: Equipped with IoT sensors for real-time monitoring of performance and maintenance needs. Predictive analytics helps prevent unexpected downtimes.

- Advanced Materials: Development of lightweight, durable, and heat-resistant belt materials with anti-static and fire-resistant properties for specific applications.

- Automation and Integration: Seamless integration with robotics and automated systems, with improved control systems for better synchronisation with production lines.

Why Choose CMS for Your Custom Conveyor Solutions

Recent innovations have elevated the capabilities of belt conveyors, ensuring they meet the demands of modern industries:

- Smart Conveyors: Equipped with IoT sensors for real-time monitoring of performance and maintenance needs. Predictive analytics helps prevent unexpected downtimes.

- Advanced Materials: Development of lightweight, durable, and heat-resistant belt materials with anti-static and fire-resistant properties for specific applications.

- Automation and Integration: Seamless integration with robotics and automated systems, with improved control systems for better synchronisation with production lines.

Why Choose CMS for Your Custom Conveyor Solutions

At CMS (Corby Mechanical Services), we’re dedicated to optimising your operations with tailored conveyor systems that deliver efficiency, safety, and long-term value.

Here’s how we do it:

1. Fully Custom-Engineered Solutions

We partner with you from concept to commissioning—studying your process requirements, future growth plans, and upstream/downstream operations—to engineer a conveyor system that meets your performance targets and budgetary goals.

2. Integrated Design and Fabrication

Our in-house design and fabrication teams collaborate closely under one roof.

This tight integration ensures rigorous quality control, faster turnaround times, and real-world validation of your system before it ever leaves our facility.

3. Enhanced Efficiency and Productivity

By analysing your material flow and eliminating bottlenecks, we automate sorting, merging, and accumulation tasks to boost throughput, reduce manual labour, and help you consistently meet delivery deadlines.

4. Advanced Safety Features

We incorporate emergency stops, guards, sensors, and other safety interlocks directly into your conveyor design—minimising manual handling of hazardous materials, reducing accident risk, and ensuring compliance with industry standards.

5. Cost Savings and Long-Term Value

While our custom systems require a higher initial investment, you’ll recoup that cost through lower labour expenses, reduced product damage, and predictive maintenance strategies that minimise downtime and repair costs over the equipment’s lifetime.

6. Flexibility, Scalability, and Integration

CMS builds conveyors to evolve with your business. You can expand or reconfigure your system as needed, and we seamlessly integrate it with robotics, automated controls, and real-time monitoring tools to support your Industry.

7. Optimised Space Utilisation

Whether you require horizontal, vertical, or overhead configurations, we tailor each system to fit your facility’s unique footprint—maximising available space without costly construction or modifications.

At CMS, we employ an end-to-end engineering and fabrication process to ensure your conveyor solution precisely matches your operational needs, delivering superior performance, safety, and return on investment today and in the future.

Contact us for a free consultation.

At CMS, we employ an end-to-end engineering and fabrication process to ensure your conveyor solution precisely matches your operational needs, delivering superior performance, safety, and return on investment today and in the future.

Contact us for a free consultation.

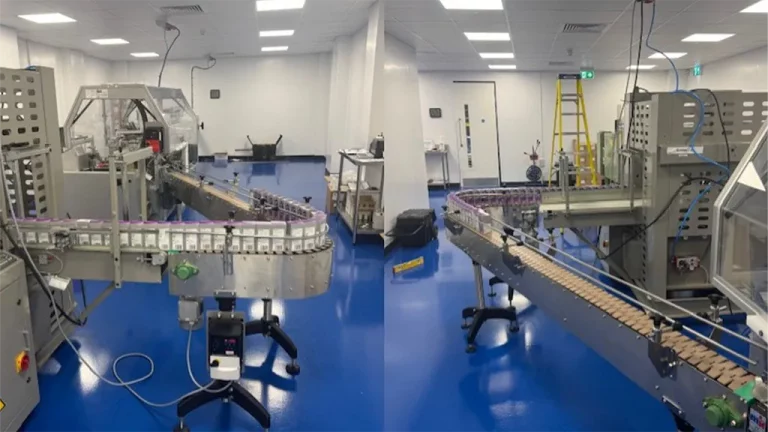

Our Latest Installation - Pharmaceutical Packaging Facility

We’ve just completed the installation of a stainless-steel modular belt transfer conveyor at a pharmaceutical packaging facility.

This turnkey system now seamlessly transports cartons from the customer’s high-speed cartoner directly into their shrinkwrap machine, ensuring hygienic handling and precise product flow.

To learn more about designing a modular conveyor system tailored to your needs, please complete the form below.Request a Belt Conveyor Quote

We provide complimentary consultations to help you select the ideal modular conveyor system for your requirements.

Learn More About the Benefits of Modular Conveyor Systems

Frequently Asked Questions

Yes, they can typically handle inclines up to 45 degrees without flights. For steeper inclines, rubber flights may be required

Yes, replacing the belt is quick and can be done within minutes

No, modular belts do not need tracking.

Yes, accumulation is possible depending on the product, with various materials available for different friction levels.

Modular Conveyor Systems offer flexibility, scalability, reduced downtime for maintenance, enhanced reliability, and cost-effectiveness compared to traditional systems

Their design allows for quick modifications and expansions without significant downtime or costs, helping businesses adapt to changing needs efficiently

Common types include belt conveyors, roller conveyors, modular plastic belt conveyors, and specialised conveyors for heavy or light loads.